- Overview

- Application & Main Features

- Main Technical Speciation

- Material Characteristic

- Control System

- Certifications

- About us

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

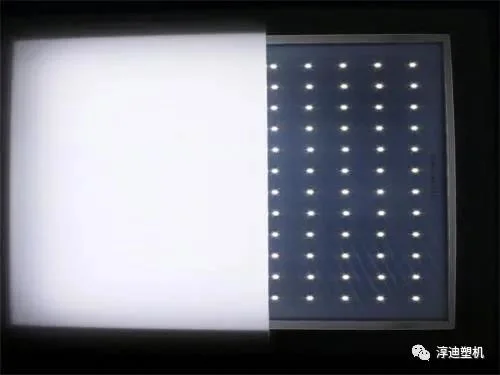

1. light weight, impact resistance, transmittance over 92%

2. compared with PC, it's more stable

3. absorbing water(0.3%--0.4%), must be dried before being processed

4. weather resistance

5. easy to process

Polycarbonates(PC), some grades are optically transparent. Easily worked, molded and thermoformed. Temperature resistance, impact resistance and optical properties.

1. Mechanical properties:

high strength and elastic coefficient, high impact strength, good fatigue resistance, good dimensional stability, there is little change in the floor at high temperature; high transparency and Free staining;

2. Heat and aging resistance:

the temperature range is wide, and the enhanced mountain temperature index reaches 120~140° (outdoor long-term aging)The chemical property is also very good

3. Solvent resistance: no stress cracking;

4. Water stability: easy to decompose when exposed to water at high temperature

Use with caution in high humidity environments;

5. Insulation performance: excellent (wet and high temperature can also maintain stable electrical performance, which is an ideal material for manufacturing electronic and electrical parts);

6. Dielectric coefficient: 3.0-3.2;

7. Insect-resistant are resistance: 120s;

8. Molding machinability: injection molding or extrusion of ordinary equipment.

| Model | MGL130/38, 45/30 | MGL120/35, 45/30 |

| Material | PC/PMMA/PS/MS | PC/PMMA/PS/MS |

| Width | 1200-2100mm | 12200mm |

| Thickness | 1.5-12mm | 1-12mm |

| Capacity | 750kg/h | 500kg/h |

Polycarbonate (PC) ,It is colorless and transparent, excellent heat aging resistance, impact resistance, excellent insulation.

The polymethyl methacrylate , or PMMA. Also known as acrylic or perspex. High transparency. Often used as a substitute for glass.

Polystyrene(PS): easy to process; transparent, cheap and insulated, including GPPS(GPPS, General-Purpose Polystyrene, commonly known as transparent benzene. Transparency 88%-92% , refractive index 1.59-1.60. Excellent electrical properties, excellent radiation resistance.) HIPS, EPS, SPS

MS:It is a commonly used transparent plastic raw material, generally injection molding and extrusion molding. The transparency is close to PMMA. It is used for optical components/toys/lampshade lighting/OA accessories/food containers/home appliances/building materials, etc.

1. PLC control for complete PET sheet/film extrusion machine.

2. SIEMENS high-end series CPU.

3. SIEMENS electrical elements, SIEMENS inverter and servo motor.

4. Centralized control, browse all the parameters in the Siemens screen touch, such as pressure, temperature, electric current, speed, etc.

5. The unique function of "key to acceleration", operation easier.

2. Quality: The quality of products is footstone of enterprise's constant development, always endeavoring to do still better, quality comes first, developing & innovative is our responsibilities;

3. Delivery: We optimize factory management, and improve production flow so as to shorten production period for you in biggest extent;

4. Cost control: We do best to lower down production cost by our inner management improvement, so as to ensure that our products are competitive enough in the market, and to realize higher performance-price ratio of our products.

| PACKAGING | Plastic film + Stretch film + wooden case |

| DELIVERY | About 120 days (all new parts) |

| SHIPPING | We place and fix the machines well into the container and check carefully before closing the container so as to ensure everything is ok for the shipment. (Use steel wire to fix machine and drying agent). We care for each and every point so that our clients could receive the machines in perfect situation. |

1. How to get the price of the sheet extrusion machine?

Please provide the details of your product requirement as clear as possible.

First, you have to tell us the detailed product parameters:

1. Final sheet width

2. Final sheet thickness

3. Capacity

4. Application of sheet product

5. The structure of sheet, if you don't know. You can send your product pintures to us.

After we receive your parameters, we will give you the suggestion.

So we can send you the offer at the first time. For designing or further discussion, it is better to contact us with E-mail, WhatsApp, Wechat or other instance ways, in case of any delays.

2. How can I get a sample to check your quality?

After price confirmation, you can require for sheet product samples to check our quality.

Free for the stock sample to check the design and quality, as long as you afford the express freight.

3. What about the lead time for mass production?

To be honest, it depends on the requirements of the specification. Generally 3-4 months.